|

Page 3 of 4

Thermal Shrinkage:

Because of their thermal expansion characteristics and changes in density, metals shrink or contract during solidification and cooling. Shrinkage causes dimensional changes and sometimes cracking and is a result of:

a) Contraction of a molten metal as it cools prior to its solidification.

b) Contraction of the metal during phase change from liquid to solid (release of the latent heat of fusion).

c) Contraction of the solidified metal (casting) as its temperature drops to the ambient temperature.

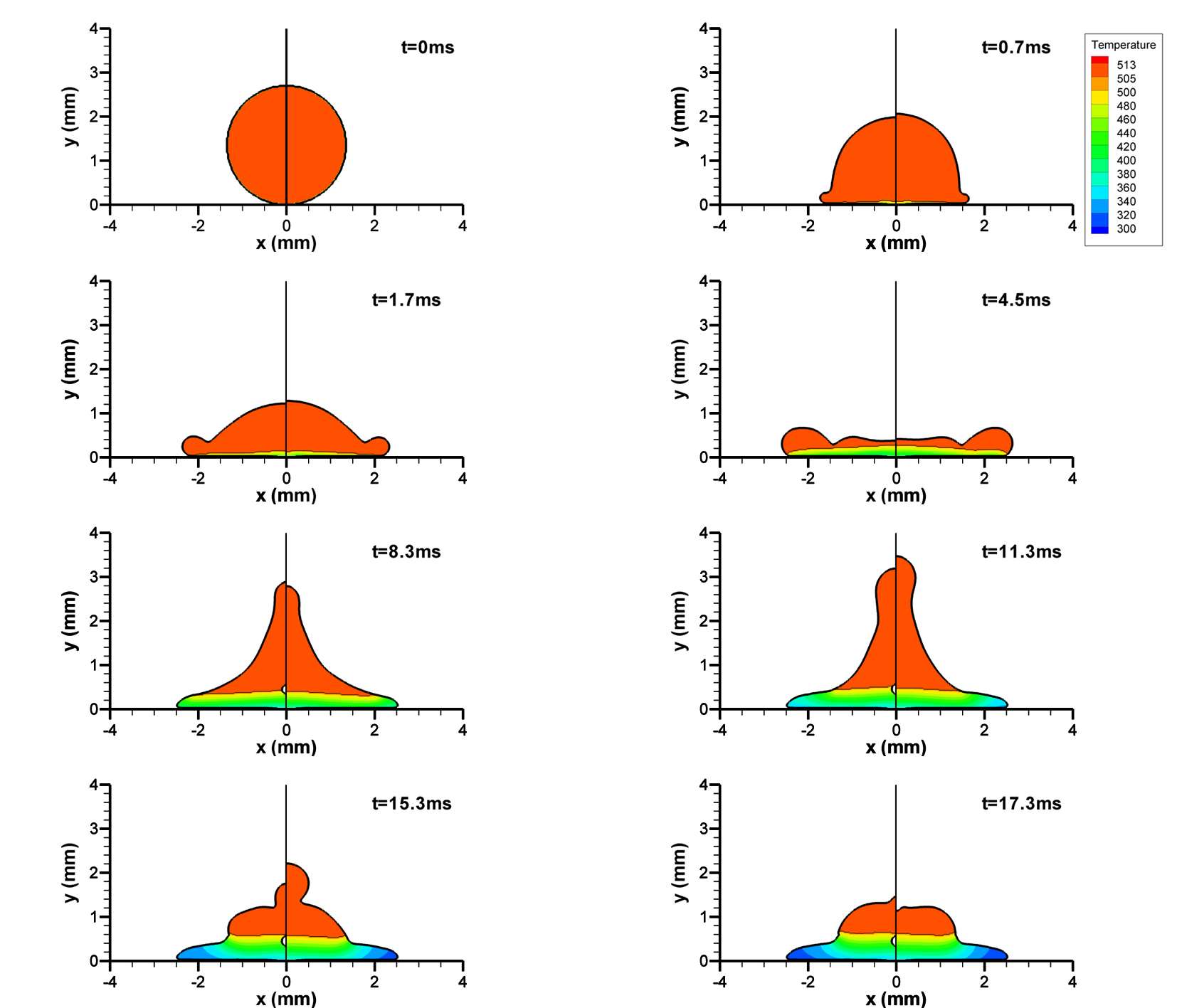

In thermal spraying processes, coatings such as various metals and alloys, carbides, and ceramics are applied to metal surfaces by a spray gun with a stream of oxyfuel flame, electric arc, or plasma arc. These coatings are formed by spraying and deposition of molten droplets on the substrate. The properties and quality of these coatings depend on many factors such as flame/laser/arc, material used for spraying, substrate and spray characteristics. As an effective phenomenon, thermal shrinkage affects the formation and integrity of the coating. Using FLUENT software, it has been found that as the molten metal droplets impinge and solidify onto a cold substrate, in comparison to the case of constant density, thermal shrinkage causes the formation of a void at the center of the solidified splat.

|